Phone: +359 876 761 742

Address: Varna, bul. Yan Hunyadi 2A

Working Hours: Monday - Friday

09:00-13:30

14:30-18:00

Days Off - Saturday and Sunday

Softelektronik offers complete diagnostics, service, and repair of the electrical system and electronic modules of electric vehicles such as BMW, Peugeot, Mercedes, and others. The Softelektronik team has extensive experience in the diagnostics, maintenance, and repair of automotive electronics for vehicles. The technicians are practically trained and certified by Bosch for working with high-voltage systems on vehicles with alternative propulsion. Softelektronik's service for hybrid and electric vehicles is equipped with the latest generation of diagnostic equipment, as well as tools created by the company for the inspection and repair of specific high-voltage systems in hybrids and electric vehicles.

It is important to obtain initial information from the driver of the electric vehicle to determine the fault that has occurred in any of the electrical modules or circuits of the electric car and to prevent its recurrence. Before proceeding with the diagnosis, it is necessary to get an idea of the symptoms, the road situation, the atmospheric conditions, and the indications to the driver from the vehicle's alert system.

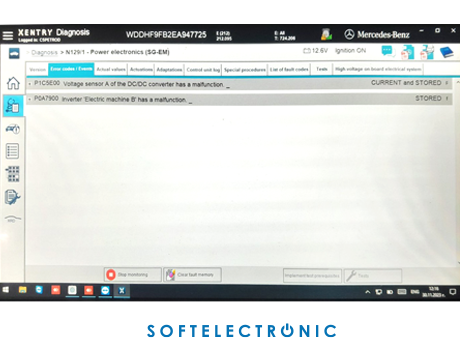

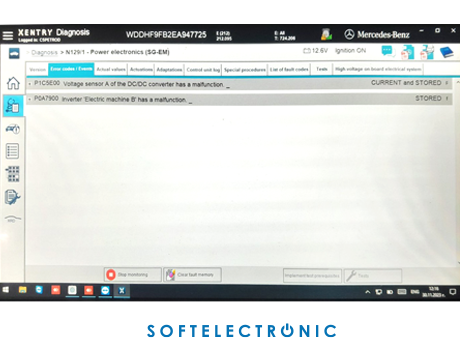

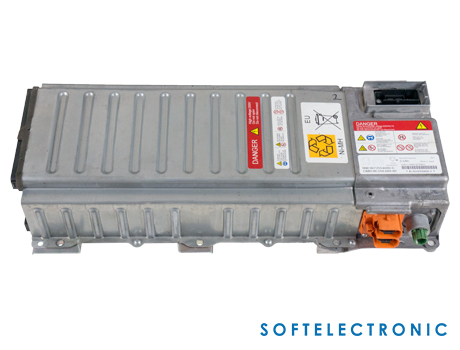

Softelektronik has diagnostic equipment and automotive testers for electric vehicles, which are part of the modern vehicle fleet in Bulgaria. Through computer diagnostics, an initial understanding of the condition of individual modules of the high-voltage battery, the inverter/converter, individual sensors, the cooling system of the high-voltage battery, and others is obtained. Auto diagnostics is an important part of performing subsequent repair of the electric vehicle after a problem is identified. The information from the computer diagnostics can help prevent the recurrence of the same fault in the repaired module. Examples are error codes in a hybrid Mercedes W221 car with a problem in the inverter/converter (SG-EM) - P0A6300, P0A6000, P0A5D00. >

⚡️⚡️⚡️ The strong currents and high voltage in the high-voltage systems of hybrids and electric vehicles can be life-threatening. For this reason, it is imperative that they be serviced by technicians who have the necessary practical training, license, and equipment to work with high-voltage systems.

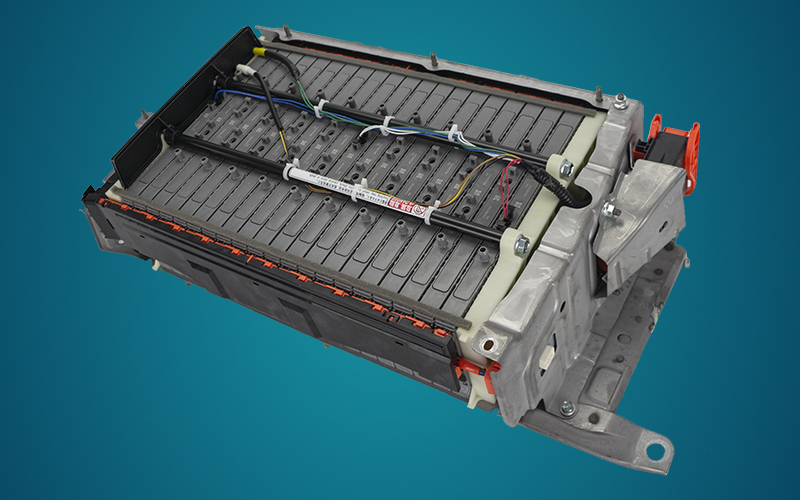

The process includes specialized equipment created in the Softelektronik laboratory for testing and determining the condition of each individual cell for all models of high-voltage batteries for electric vehicles. Through a series of cycles of full charging and discharging, the "healthy" and damaged cells, as well as the overall condition of the packs in the battery, are determined. The diagnosis also uses a specialized thermal camera, which monitors the proper functioning of individual cells and packs and the condition of electrical connections between components in the battery. The operation of temperature, voltage, and resistance sensors is also checked.

The process applies to the healthy cells in the battery packs. After a series of full discharge and charging cycles, the voltages in the individual cells are equalized. The need for balancing (reconditioning) of healthy cells may arise due to the appearance of reversible crystallization in the substances forming the cell of the electric vehicle battery as a result of normal operation. This process can lead to a decrease in the voltage of the cell and consequently to an overall decrease in the voltage in the pack and the battery. Through so-called deep discharge and full charging, decrystallization is performed, thus restoring the optimal operating voltage of the cell. After balancing, the battery capacity can be increased compared to the condition before the process.

After identifying irreversibly damaged cells in the battery of the electric vehicle, the cause of their damage is sought if it is not related to the normal operation of the system. The possible cause may lie in disrupted cooling of the battery, damaged electronic modules, poor contact connections, and others. Softelektronik can supply new high-quality cells for a wide range of hybrid vehicles such as Mercedes, Peugeot, Toyota, and others. After replacing the necessary cells in the battery, a balance is again performed, during which the operation of all cells and packs is checked.

The battery management unit for electric vehicles collects information about the voltage of the cells and blocks, their temperature, and their internal resistance. After analyzing the data, it manages the proper cooling, charging, and discharging of the hybrid battery during the operation of the hybrid vehicle. Softelektronik is one of the few companies in the world that can repair BMS for hybrid and electric vehicles.

Corrosion on the terminals, busbars, and fastening elements (nuts and others) of the electrical connections in the battery can lead to improper operation of the battery and a reduction in its capacity. The cause could be a breach in the battery's hermetic seal, leakage of the cooling agent, substances (such as electrolytes) released from the accumulator cells, flooding, dampening, and others. The corroded elements are dismantled, and the cleaning may include mechanical processes and treatment with specialized chemicals depending on the extent of the corrosion.

The experienced service technicians at Softelektronik can identify the cause of a fault in the electrical circuit or a given module in the electric vehicle and remove it before it has caused a costly repeat repair.

To ensure the efficiency of the modules of the electric drive system of the electric vehicle, it is necessary to maintain the operating temperature within a certain range. This requires a more complex system for optimal thermal management. Timely maintenance of the cooling system can prevent damage to key components such as the motor-generator, inverter, or battery. Softelektronik can perform repairs on the electronics of modules from the cooling system of the electric vehicle, such as the electric compressor.

Softelektronik performs diagnostics and repairs on a wide range of electronic modules for electric vehicles such as electronic controls, locking systems, lighting systems, displays, multimedia, navigation, and others.